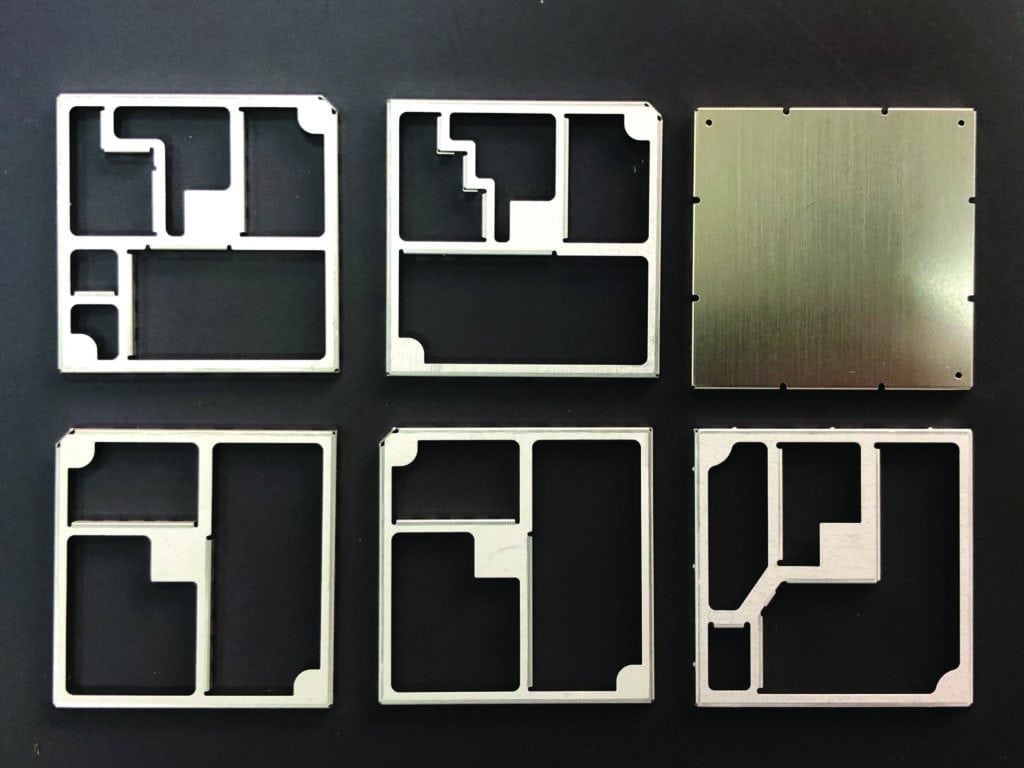

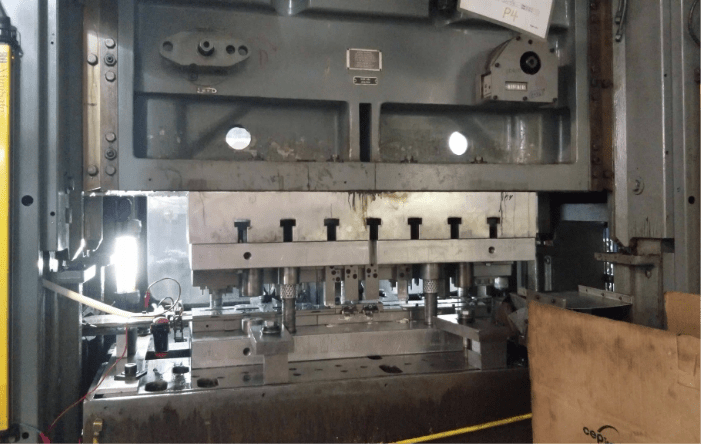

What Is Metal Stamping? Various industries require small metal parts made precisely and in high quantities. At CEP Technologies Corporation, we specialize in miniature to small custom progressive stamping projects. Metal stamping is a high-speed manufacturing method that transforms flat metal sheets into precise, functional parts. Using dies and presses, this technique produces metal stamping…

What Is Progressive Metal Stamping