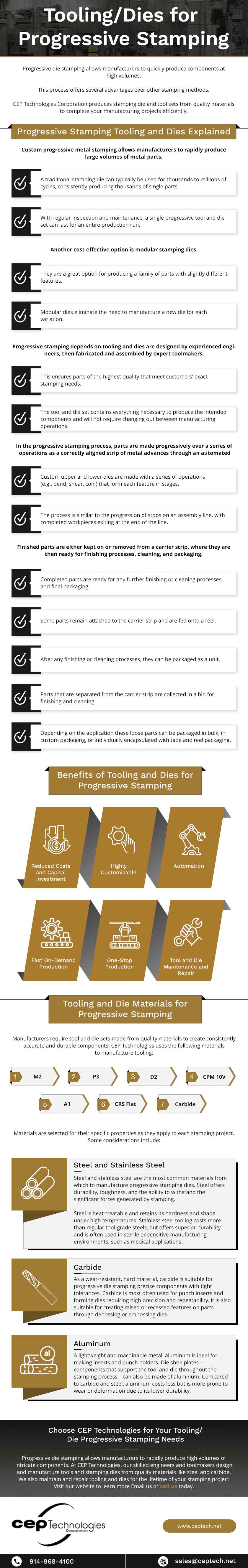

Progressive die stamping allows manufacturers to quickly produce components at high volumes. This process offers several advantages over other stamping methods. CEP Technologies Corporation produces stamping die and tool sets from quality materials to complete your manufacturing projects efficiently. Learn more about the benefits and materials used for progressive stamping tool and die sets.

Progressive Stamping Tooling and Dies Explained

Custom progressive metal stamping allows manufacturers to rapidly produce large volumes of metal parts. A traditional stamping die can typically be used for thousands to millions of cycles, consistently producing thousands of a single part. With regular inspection and maintenance, a single progressive tool and die set can last for an entire production run.

Another cost-effective option is modular stamping dies. They are a great option for producing a family of parts with slightly different features. Modular dies eliminate the need to manufacture a new die for each variation.

Progressive stamping depends on tooling and dies are designed by experienced engineers, then fabricated and assembled by expert toolmakers. This ensures highest quality parts that meet customers’ exact stamping needs. The tool and die set contains everything necessary to produce the intended components and will not require changing out between manufacturing operations.

In the progressive stamping process, parts are made progressively over a series of operations as a correctly aligned strip of metal advances through an automated press. Custom upper and lower dies are made with a series of operations (e.g., bend, shear, coin) that form each feature in stages. The process is similar to the progression of stops on an assembly line, with completed workpieces exiting at the end of the line.

Finished parts are either kept on or removed from a carrier strip, where they are then ready for finishing processes, cleaning, and packaging. Completed parts are ready for any further finishing or cleaning processes and final packaging. Some parts remain attached to the carrier strip and are fed onto a reel. After any finishing or cleaning processes they can be packaged as a unit. Parts that are separated from the carrier strip are collected in a bin for finishing and cleaning. Depending on the application these loose parts can be packaged in bulk, in custom packaging or individually encapsulated with tape and reel packaging.

Benefits of Tooling and Dies for Progressive Stamping

Progressive tool and die sets deliver several benefits, including:

- Reduced Costs and Capital Investment: With components spaced close together on the coil strip, progressive stamping decreases scrap waste during production. This stamping method forms parts efficiently because all of the needed operations are contained within a single die that is designed to minimize scrap and waste in production. What’s more, it costs less to create a single, complex die than multiple single-operation dies. For parts with small variations, modular dies are a cost-effective option.

- Highly Customizable: The ability to customize dies with intricate details allows manufacturers to produce various complex parts, including but not limited to contacts, tabs, clips, and pins.

- Automation: Progressive die stamping can automatically process hundreds of parts per minute once the tooling is set up. CEP Technologies’ skilled toolmakers make quality dies that produce stamped parts meeting exact tolerances with minimal error. Dies can also be adjusted or repaired to keep them performing properly long-term.

- Fast On-Demand Production: Progressive stamping is a rapid manufacturing method. CEP Technologies stores clients’ tooling and dies in-house. We also provide maintenance and upkeep of all tooling and dies for the lifetime of the project, allowing the OEMs and suppliers that work with us to keep up with part demand.

- One-Stop Production: Working with a single vendor from start to finish is cost-effective and convenient. CEP Technologies offers everything from rapid prototyping to cleaning, finishing, and customized packaging.

- Tool and die maintenance and repair: Even the most durable dies require maintenance to ensure quality stampings that are within tolerances. CEP Technologies will monitor tooling and die sets for wear and damage, maintaining and repairing them as needed for the life of your project.

Tooling and Die Materials for Progressive Stamping

Manufacturers require tool and die sets made from quality materials to create consistently accurate and durable components. CEP Technologies uses the following materials to manufacture tooling:

- M2

- P3

- D2

- CPM 10V

- A1

- CRS Flat

- Carbide

Materials are selected for their specific properties as they apply to each stamping project. Some considerations include:

-

- Steel and stainless steel: Steel and stainless steel are the most common materials from which to manufacture progressive stamping dies. Steel offers durability, toughness, and the ability to withstand the significant forces generated by stamping.

Steel is heat-treatable and retains its hardness and shape under high temperatures. Stainless steel tooling costs more than regular tool-grade steels, but offers superior durability and is often used in sterile or sensitive manufacturing environments, such as medical applications.

- Carbide: As a wear-resistant, hard material, carbide is suitable for progressive die stamping precise components with tight tolerances. Carbide is most often used for punch inserts and forming dies requiring high precision and repeatability. It is also suitable for creating raised or recessed features on parts through debossing or embossing dies.

- Aluminum: A lightweight and machinable metal, aluminum is ideal for making inserts and punch holders. Die shoe plates—components that support the tool and die throughout the stamping process—can also be made of aluminum. Compared to carbide and steel, aluminum costs less but is more prone to wear or deformation due to its lower durability.

Choose CEP Technologies for Your Tooling/Die Progressive Stamping Needs

Progressive die stamping allows manufacturers to rapidly produce high volumes of intricate components. At CEP Technologies, our skilled engineers and toolmakers design and manufacture tools and stamping dies from quality materials like steel and carbide. We also maintain and repair tooling and dies for the lifetime of your stamping project.

Read more about our progressive die stamping process for precision parts and custom metal stamping services, or request a quote for specific pricing details.