CEP Technologies Corporation is a global supplier of progressive die stamped, miniature to small parts. From in-home power delivery to electrical equipment and appliances to individual electronic devices, our capabilities allow us to manufacture components for electric and electronic applications in the most broad sense. We provide our customers with custom, miniature to small components from strips of metal as thin as .002” to .080” thick.

CEP Technologies Corporation is a global supplier of progressive die stamped, miniature to small parts. From in-home power delivery to electrical equipment and appliances to individual electronic devices, our capabilities allow us to manufacture components for electric and electronic applications in the most broad sense. We provide our customers with custom, miniature to small components from strips of metal as thin as .002” to .080” thick.

Benefits of Progressive Metal Stamping for Electronics and Power Delivery

Progressive die stamping is a natural fit for the electrical, electronics, and power delivery industries. With a growing variety of components and devices designed to be smaller and smaller, the need for many types of very tiny metal parts is expanding throughout these industries.

A stamper like CEP Technologies offers several benefits to manufacturers in these industries, including:

- Custom parts for a variety of applications including power delivery, electrical equipment, electronic devices and household appliances. Progressive stamping can be widely used for components within these industries.

- Custom stamping capabilities to your specifications, with tight tolerances, so you get exactly what you need, not just “close enough” or off-the-shelf components.

- In-house engineering expertise in precision stamping to work with your part design and optimize it for the manufacturing process. Our team is mindful of the interplay between part performance, material selection, cost, and lead time.

- In-house manufacturing and maintenance of the tooling and dies for the life of your project so they’re always available and part quality remains consistent.

- One-stop production to save time and money with a single vendor. We offer several options for finishing, cleaning, and packaging.

Electrical Components Created With Progressive Metal Stamping

Explore our interactive landscape to see the electrical, electronic and power delivery applications CEP Technologies can manufacture stamped components for, and how each application plays a part in a home setting:

We also manufacture the tiny metal parts that go into power protection equipment. Learn more on our Telecommunications page!

Explore our interactive car to see the miniature and small parts we make for each area of a car.

We can also stamp components for security system peripheral equipment such as in control panels, mesh network routers, battery backup systems, and more. Learn more about our security system capabilities!

We can also manufacture the small metal parts used in a water meter’s system, including the flow register and transmission device.

Progressive stamping is used to create miniature to small parts that are formed through a series of operations as a thin strip of metal feeds through a press. A few common part types include:

- Battery contacts

- Switch contacts

- Relay components

- EMI/RFI shields

- Clips, tabs, latches, brackets, plates and more

Each manufacturer designs these and other part types for their unique products, therefore most progressive stamping work CEP Technologies does is custom.

Exterior Applications

Examples of electrical and power delivery products that incorporate progressive stamped parts used in outdoor/external applications include:

- Transformers (on utility poles)

- Service drop fixtures

- Solar panels

- Outdoor lighting fixtures

- Water and electric meters

- Air conditioning units

Interior Applications

Stamped components for electrical, electronics and power delivery products are also used in many interior applications including:

- Breaker boxes and service panels

- Outlets

- Appliances (i.e., dishwashers, stoves/ovens, microwaves, washer/dryer)

- Home security systems

- Heating and cooling systems

- Generators

- Cars (the electrical components in them, like for the infotainment system)

- Garage door openers/actuators

- Indoor lighting fixtures

- “Smart” devices (i.e., thermostats, “smart home” systems, TVs, bluetooth devices)

- Routers / network security routers

- CEP can stamp parts for both AC and DC powered equipment and devices

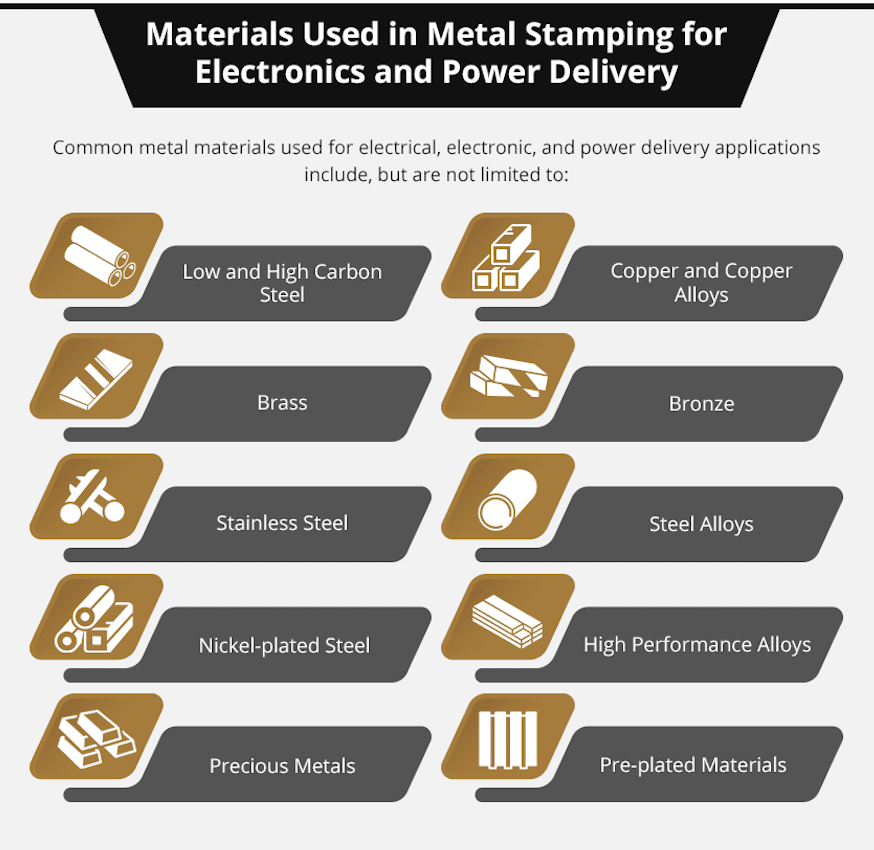

Materials Used in Metal Stamping for Electronics and Power Delivery

Characteristics like conductivity, solderability, strength, malleability, corrosion resistance, and others may be considered when selecting the best material for a part. Cost and availability are also important factors.

Common metal materials used for electrical, electronic, and power delivery applications include, but are not limited to:

- Low and high carbon steel

- Copper and copper alloys

- Brass

- Bronze

- Stainless steel

- Steel alloys

- Nickel-plated steel

- High performance alloys

- Precious metals

- Pre-plated materials

Our team can work with you to select materials that meet your requirements. We can also provide coatings, polishing, heat treatment, and anodizing services.

Quality Precision Progressive Stamped Parts From CEP Technologies

No matter where your products fit into the world of power delivery, electrical equipment and electronics, they likely include tiny, precision components. At CEP Technologies, we understand these small pieces are just as critical to your success as parts many times their size. We are committed to meeting and exceeding our customer’s requirements on every project.

We are IATF 16949:2016 and ISO 14001:2015 certified with TUV Rheinland of North America and in-house engineering expertise to manufacture custom parts to your specifications. Our team is always ready to learn about your next project so please get in touch or request a quote to learn more. Free custom sample kits are also available.