As an experienced global supplier of miniature to small progressive stamped parts, CEP Technologies Corporation serves many industries. Here, you’ll learn how our precision stamping expertise benefits the needs of the telecommunications industry, as well as some of the materials used for common telecommunications applications.

Precision Metal Stamping in the Telecommunications Industry

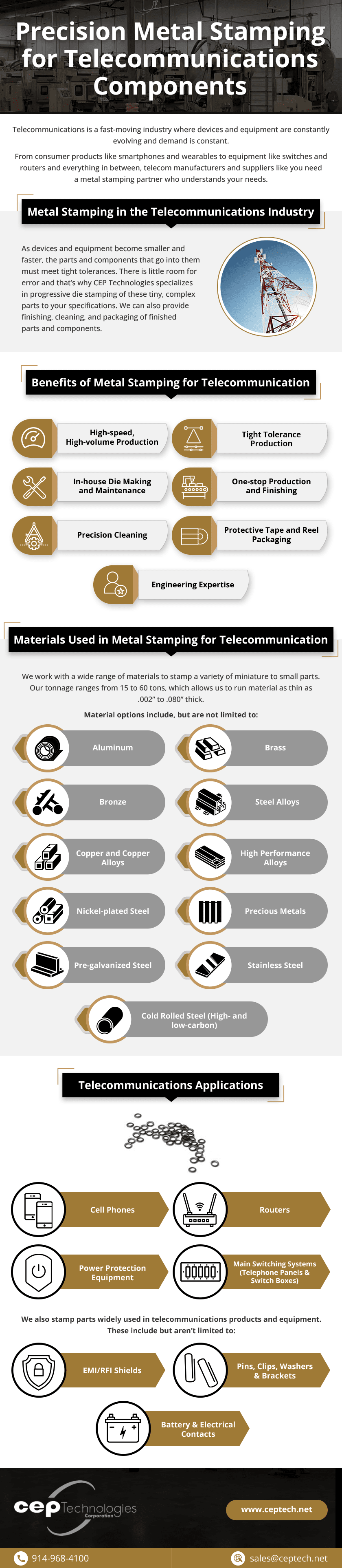

As devices and equipment become smaller and faster, the parts and components that go into them must meet tight tolerances. There is little room for error and that’s why CEP Technologies specializes in progressive die stamping of these tiny, complex parts to your specifications. We can also provide finishing, cleaning, and packaging of finished parts and components.

Benefits of Metal Stamping for Telecommunication

Progressive stamping is a highly automated process, which makes it an excellent choice for medium and large production runs. Our metal stamping capabilities offer these benefits:

- High-speed, high-volume, tight tolerance production. Save money with efficient production on automated presses that can run hundreds of parts per hour.

- Engineering expertise. Our team includes engineers to review your part prints for manufacturability and to find ways to use less material, fewer steps, or make minor changes that add up to savings and highest quality.

- In-house die making and maintenance. CEP Technologies will build tooling and dies, and keep them clean and in good working order for the lifetime of your production run. You’ll know we always have them available for your stamping projects, and you can expect consistent quality part after part. Of course, you also have the choice to transfer your existing tooling. Learn more about your options here.

- One-stop production and finishing. All parts are stamped to your specifications with highest-quality materials. We also offer many finishing processes including plating, polishing, heat treating and anodizing. Finished stampings are cleaned and packaged for shipping to your facility in ready-to-use condition.

- Precision cleaning. CEP Technologies is able to clean precision stamped parts to specifications, including holding particle sizes to less than 200µm for parts that have pre-plated raw material.

- Protective tape and reel packaging. Parts remain in ready-to-use condition during shipping and in storage with tape and reel packaging that encapsulates each individual part. We are also able to design customized packaging depending on your needs. Read how we helped one customer redesign their packaging for part separation and ease of access.

Materials Used in Metal Stamping for Telecommunication

We work with a wide range of materials to stamp a variety of miniature to small parts. Our tonnage ranges from 15 to 60 tons, which allows us to run material as thin as .002” to .080” thick.

Material options include, but are not limited to:

- Aluminum

- Brass

- Bronze

- Cold rolled steel (High- and low-carbon)

- Copper and copper alloys

- High performance alloys

- Nickel-plated steel

- Precious metals

- Pre-galvanized steel

- Stainless steel

- Steel alloys

Telecommunications Applications

Progressive die stamping is a fast and reliable method for manufacturing many of the miniature to small sized parts used in telecom devices and equipment. This includes tiny yet critical parts and components that go into devices and equipment like:

- Cell phones

- Main switching systems for telephone panels and switch boxes

- Power protection equipment

- Routers

We also stamp parts widely used in telecommunications products and equipment. These include but aren’t limited to:

- EMI/RFI shields

- Pins, clips, washers and brackets

- Battery and electrical contacts

Quality Precision Metal Stampings from the Experts at CEP Technologies

Poor quality parts or late deliveries have cumulative effects on your business because they impact subsequent steps in the manufacturing process. You can reduce the risks of part or product failure, and improve your ability to supply your own customers with quality products and assemblies. CEP Technologies is an integral part of this supply chain, giving you progressive stampings on time, to specification and tolerance, and packaged securely.

Our global production facilities can handle medium to high volume production runs. Whether it is 25,000 pieces a year or 100,000,000 pieces a year, we can meet or exceed your requirements. Please contact us, request a quote or a free sample kit to see some examples for yourself.