Custom Metal Stamping

Here we’ll specifically take a close look at progressive metal stamping for miniature to small parts. What follows is a comprehensive overview of the benefits of progressive stamping, how it works, common stamping operations performed in the press, types of metals suitable for progressive stamping, and industries and applications that rely on it.

What is Metal Stamping?

Benefits of Metal Stamping

Metal stamping is an efficient process for manufacturing high volumes of parts with great accuracy and precision. It is a high speed, automated process that can create hundreds to thousands of identical parts in a day, depending on part complexity and the speed of the press feed.

There are many cost- and time-saving advantages to working with a metal stamper like CEP such as:

- Custom production based on your concept or drawings, and expert support from our design and engineering team

- Fast, high-volume production

- Ability to achieve complex part geometries and features with tight tolerances for dimensions, angles, flatness, technical cleanliness, etc.

- Wide range of metal types available, including pre-plated material

- Ability to draw on your stamper’s experience to optimize your design and materials for efficient manufacturability and cost effective production

- High capacity for part availability when you need it

- One-stop production from a single vendor with finishing processes, cleaning, packaging and tape and reel encapsulation in one place

How Does Metal Stamping Work?

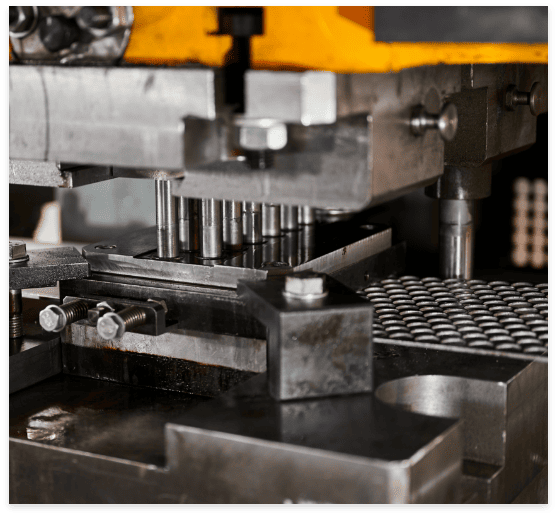

Miniature to small part metal stampings are made from very thin, narrow strips of metal that are fed into a specialized press from a coil. The strip is advanced through the machine and through custom-made upper and lower tooling and dies that align the strip and contain a series of sequential features (i.e., stations) to form and cut the metal in a series of steps.

The press strikes the material repeatedly with tonnages of 15 to 60 tons, depending on the material properties, thickness, and design requirements. With each stroke of the press the strip advances and each part is created step by step in rapid succession. Because the material is carefully aligned as it travels through the press, parts can be stamped within very tight tolerances, often to within hundredths to thousandths of an inch.

The finished parts are automatically removed from the carrier web strip and exit the press into a collection bin where they are ready for finishing processes, cleaning, and packaging.

Tiny stampings like these can also be produced from small blanks of metal, for example CEP’s maximum blank size is 6×6 inches square.

A variety of cutting, shaping, and material removal operations may be used in progressive stamping including:

Critical to the operations that happen inside the press are the tooling and dies that perform them. All tooling and dies are custom manufactured, taking into account the total production volume, material being stamped, and other factors.

Dies must be made in precise shapes that will remain durable for thousands or millions of strikes. Some stampers, like CEP, add value to their stamping services by including maintenance and repairs for the lifetime of the part production. Customers also have the choice of transferring existing tooling and dies or having new ones made for the project.

Finally, make sure your stamper will work with you for Production Part Approval Process (PPAP) documentation, test production runs, and all the steps in bringing production up to full speed.

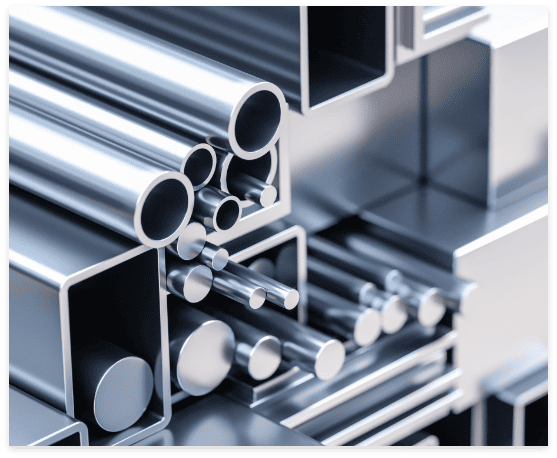

Types of Metals

Many types of material are available in coil form for progressive stamping. Depending on the application there may be multiple metals suitable for a project, such as:

- Stainless Steel

- Aluminum

- High- and Low-carbon Cold Rolled Steel

- Pre-galvanized Steel

- Nickel-plated Steel

- Precious Metals

- Brass

- Bronze

- Copper

In general, miniature to small parts are stamped from metals in thicknesses from 0.002” to 0.080”. Pre-plated materials can also be used to save on manufacturing time and costs in certain applications.

The properties of each metal and how it “behaves” when formed or bent influence its suitability for a part or stamping operation. A stamper like CEP can make recommendations by taking into account the physical stresses, temperatures, conductivity requirements, solderability, strength, and hardness needs of the design. For example, brittle metals may be more difficult to bend without cracking, or certain types of steel or aluminum may be more susceptible to galling than others. Read more about material considerations here.

Another important consideration for custom stamped parts are post-production and finishing processes. Some common options include heat treating, full electroplating or selective plating, photo-chemical etching, laser cutting, and coatings such as tin. These processes can enhance the performance or durability of the finished part, or save on overall costs. For example, instead of stamping a battery contact out of expensive copper coil, it may be possible to use a less expensive metal for the part and then selectively plate only the critical portions with copper, thereby using less copper and saving money.

Stampers may also offer precision cleaning of finished parts to technical specifications, and custom packaging and tape and reel encapsulation to protect parts in shipping and storage.

CEP offers comprehensive custom stamping, post-production, and finishing services to meet your needs for quality and value.

Industries Served

Progressive metal stamping is used in a variety of industries for countless applications. Common types of parts manufactured include customized versions of pins, clips, tabs, brackets, plates, and other specialized components.

The following are examples of the ways in which different industries utilize progressive stamping for miniature and small parts:

Automotive and EV/e-mobility parts for OEMs and aftermarket manufacturers

Examples include components for electronics, door locking systems, infotainment systems, GPS systems, advanced driver assistance systems (ADAS), sensor parts, fuel pumps, fuse panels, heat sink plates, and more. Aerospace and agricultural vehicles are included.

Electrical and electronic devices, systems, and products

This includes home, business, and industrial electrical and electronic applications like battery and switch contacts, relay components, EMI/RFI shields, lighting fixtures, “smart” home management devices, remote controls, appliances, and security systems.

Lighting components

These are industrial, commercial, and consumer/residential lighting applications such as switches, contacts, clips, and other miniature to small components used in fixtures and peripheral equipment.

Medical and healthcare devices, equipment, and settings

Emerging and established medical devices and technologies require tiny stamped parts for things like disposable/single-use IV pumps, wearable devices, imaging equipment, device housings, and diagnostic and treatment tools.

Defense and military applications

This includes parts and components used in telecommunications, electrical, electronic, and vehicle mechanical and electronic systems that are tailored to military and defense use.

Telecommunications systems and equipment

Examples include parts used in main switching systems for telephone panels/switch boxes, power protection equipment, and routers as well as pins, clips, contacts, and brackets that secure components.

Progressive metal stamping is a versatile manufacturing process that touches so many products, end-users, and industries. From parts that go into consumer products and industrial equipment, to parts that stay “behind the scenes” holding components in place, and from components that enable vehicle’s ignition system, and those that keep electronic devices operating correctly

At CEP Technologies Corporation we will partner with you from concept, design, and prototyping through material sourcing and production. We offer customers medium to high volume annual production runs of 25,000 to 100,000,000 pieces.

Ready to start your next stamping project?

You can see samples of our work by requesting a free sample part kit or contacting us for a free quote.