CEP Technologies Corporation supplies miniature to small progressive stamped parts to customers worldwide in many industries. In the automotive industry at large, we serve OEMS, their suppliers, and automotive-adjacent manufacturers by providing custom stamped parts that meet design specs and tolerances. We also offer a full selection of standard progressive die stamped spark plug and distributor terminals. Below, we’ll explain our automotive metal stamping capabilities and services.

CEP Technologies Corporation supplies miniature to small progressive stamped parts to customers worldwide in many industries. In the automotive industry at large, we serve OEMS, their suppliers, and automotive-adjacent manufacturers by providing custom stamped parts that meet design specs and tolerances. We also offer a full selection of standard progressive die stamped spark plug and distributor terminals. Below, we’ll explain our automotive metal stamping capabilities and services.

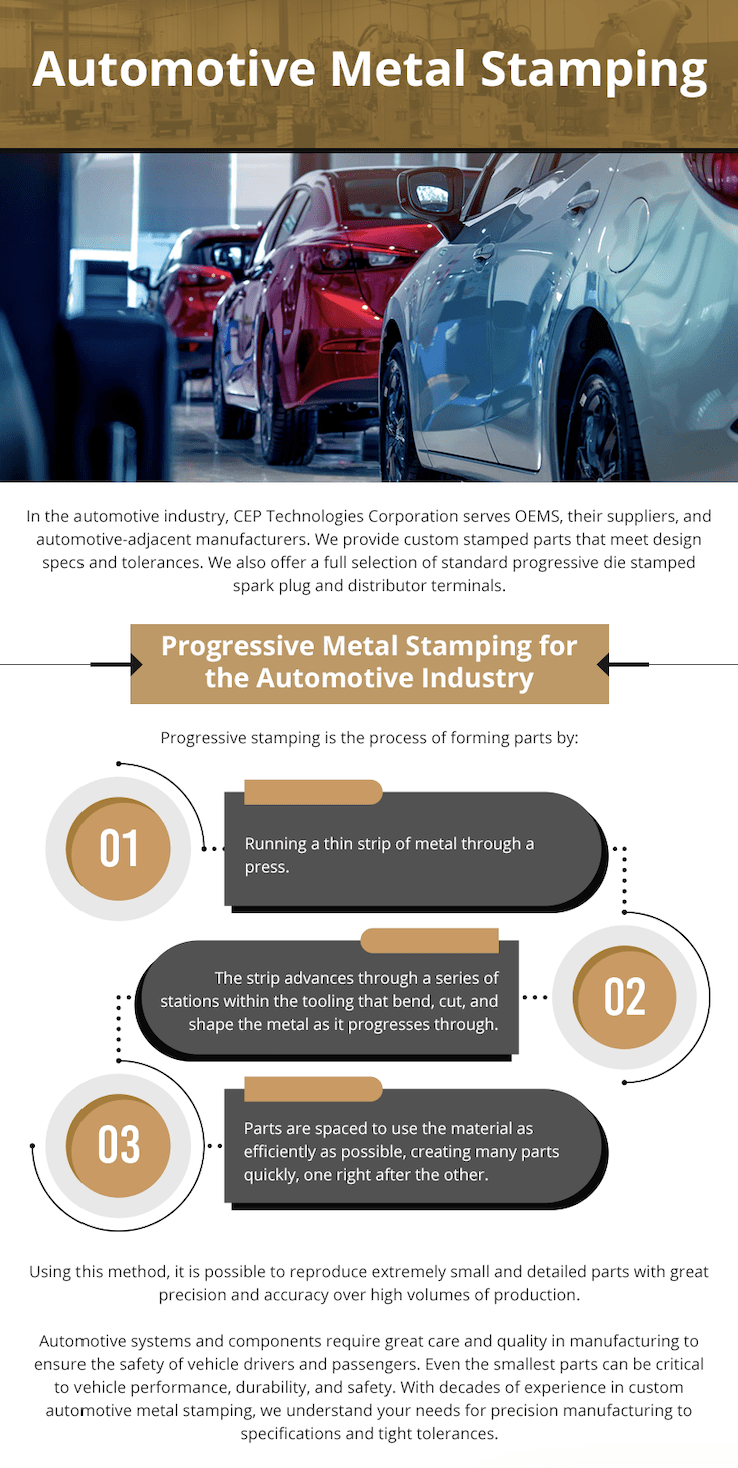

Progressive Metal Stamping for the Automotive Industry

Progressive stamping is the process of forming parts by running a thin strip of metal through a press. The strip advances through a series of stations within the tooling that bend, cut, and shape the metal as it progresses through. Parts are spaced to use the material as efficiently as possible, creating many parts quickly, one right after the other. Using this method, it is possible to reproduce extremely small and detailed parts with great precision and accuracy over high volumes of production.

Automotive systems and components require great care in manufacturing to ensure the safety of vehicle drivers and passengers. Even the smallest parts can be critical to vehicle performance, durability, and safety. With decades of experience in custom automotive metal stamping, we understand your needs for precision manufacturing to specifications and tight tolerances.

Metal Stamped Parts for Automotive Applications

We work with a wide range of materials to stamp miniature to small parts based on your part prints and CAD files. Our press tonnage ranges from 15 to 60 tons, which allows us to run material as thin as .002” to .080” thick. Common materials used include, but are not limited to, steel and steel alloys, aluminum, copper, brass, and nickel.

As a custom manufacturer, we stamp many unique and proprietary components for our customers; however, we also manufacture many types of custom pins, clips, tabs, contacts, plates, and more. Our stampings can be used throughout modern vehicles in mechanical and electronic systems as well as many vehicle accessories, such as:

- Battery contacts

- E-mobility systems

Throttle components

- Key fobs

- Door locks

- Fuel pumps

- Fuse panels

- Infotainment system components

- Ignition systems

- Antenna components

- EMI/RFI shields

- GPS systems

- ADAS (advanced driver assistance systems)

- Sensors (e.g., engine knock, transmission, ADAS-related)

- Heat sink panels for electronics

- Vehicle communications systems

While we focus on custom progressive stampings, we also offer a full selection of standard progressive die stamped spark plug and distributor terminals which are in stock and available with short lead times.

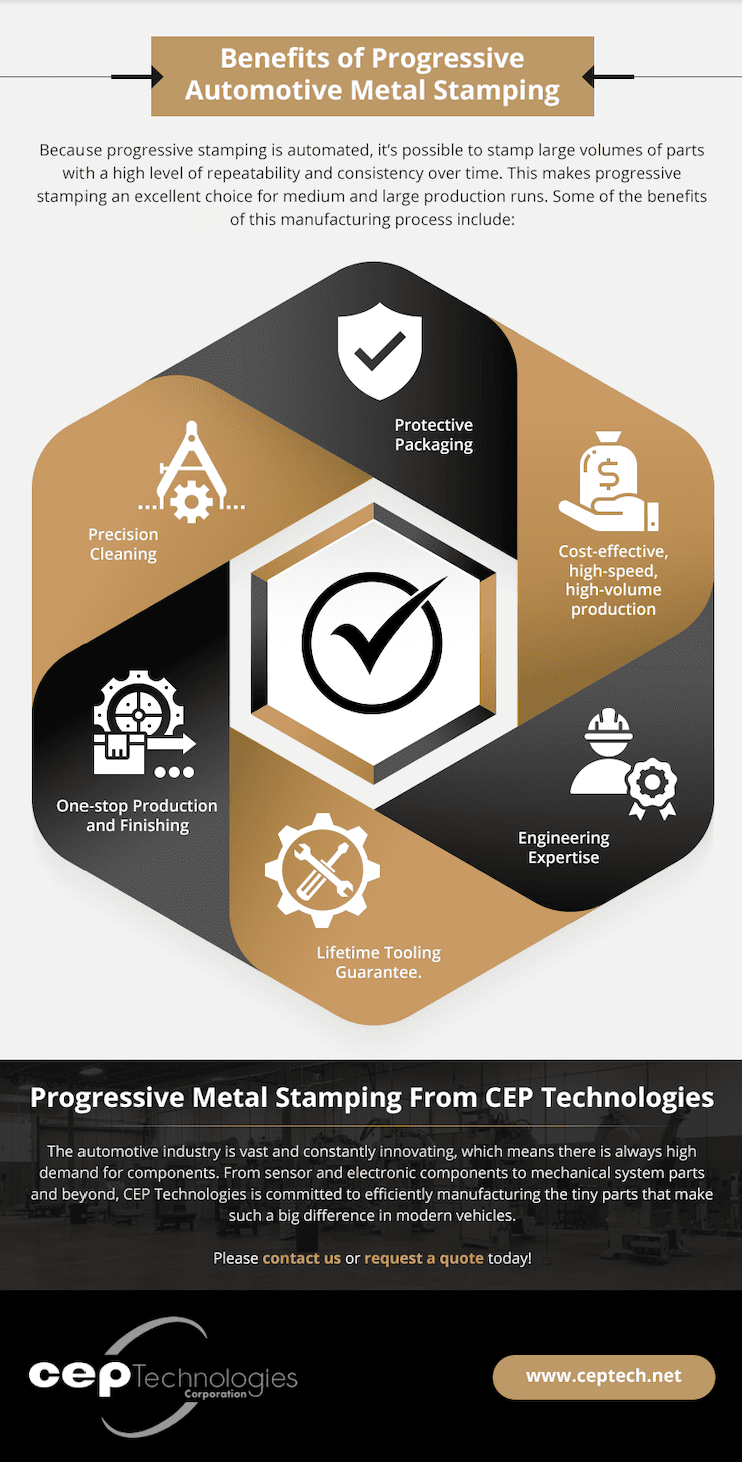

Benefits of Progressive Automotive Metal Stamping

- Cost-effective, high-speed, high-volume production. Automated presses can run hundreds of parts per hour to tight tolerances, saving time, materials, and money.

- Engineering expertise. CEP’s team of in-house engineers reviews your part prints and specifications to find ways to use less material, fewer steps, or make minor changes that make parts more efficient to manufacture without compromising quality.

- Lifetime tooling guarantee: In-house die making and maintenance. We have the capability to build custom tooling and dies for your parts, maintain, and store them for the lifetime of your production run. If you prefer, you may also transfer your existing tooling to us for maintenance and production. Learn more here.

- One-stop production and finishing. We stamp parts to your specifications with highest-quality materials. Finishing processes are also available including plating, polishing and heat treating. All stampings are cleaned and packaged and shipped to your facility in ready-to-use condition.

- Precision cleaning. We can clean stamped parts to meet your requirements, including holding particle sizes to less than 200µm for parts made from pre-plated raw material.

- Protective packaging. We use tape and reel packaging to encapsulate each individual part, or we can design customized packaging depending on your needs. Learn more here.

Progressive Metal Stamping From CEP Technologies

The automotive industry is vast and constantly innovating, which means there is always high demand for components. From sensor and electronic components to mechanical system parts and beyond, CEP Technologies is committed to efficiently manufacturing the tiny parts that make such a big difference in modern vehicles.

We are IATF 16949:2016 certified with TUV Rheinland of North America that can handle medium to high volume production, as well as prototyping, in 10 business days or less. A full line of standard ignition terminals is also available. You may request a free sample kit to see examples of our work.

Please contact us or request a quote today!

Throttle components

Throttle components