CEP Technologies Corporation is a global supplier of progressive die stamped, miniature to small parts for customers in many industries. Our experience with a wide variety of part geometries and metals means we can provide the highest quality parts to your specifications. Here we’ll focus on our progressive metal stamping capabilities for the medical and healthcare industries.

Progressive Metal Stamping in the Medical Industry

The medical industry evolves at a rapid pace, developing new therapies, tools, and technologies to treat patients and manage their care all the time. As a result, there is a constant need for the parts that go into the latest devices and equipment. What’s more, single-use and other disposable medical and healthcare products require an ongoing supply of components.

Whether you manufacture a finished product, supply an assembled component that goes into devices or equipment, or both, you need a stamping partner who is reliable and knowledgeable about your industry and your needs. CEP Technologies specializes in progressive die stamping of the tiny, complex parts that are critical to safe and effective medical devices. We can also provide finishing, cleaning, and packaging of finished parts and components.

Medical Device Components Created With Metal Stamping

When it comes to medical and healthcare applications, the quality of raw materials, such as stainless steel, cold rolled steel, or copper, is just as important as ensuring parts are free from defects. We have the ability to source the materials you need from our network of metal suppliers.

CEP Technologies can manufacture custom components for a variety of medical equipment and devices, as seen in these interactive hospital rooms.

Learn more about how we create stamped components for IV pumps.

We can manufacture custom components for applications such as:

- Disposable/single-use IV pumps

- Wearable devices

- Imaging equipment

- Device housings

- Diagnostic and treatment tools

- Components for instrumentation

- EMI/RFI shielding for medical electronics and wireless devices

- And more

For a real-world example, check out this case study. You’ll see how we worked with a design for a medical pump component that helps regulate fluid drip for an IV line. Our team optimized the manufacturing steps for efficient production, resulting in a minimum annual production volume of 20 million parts.

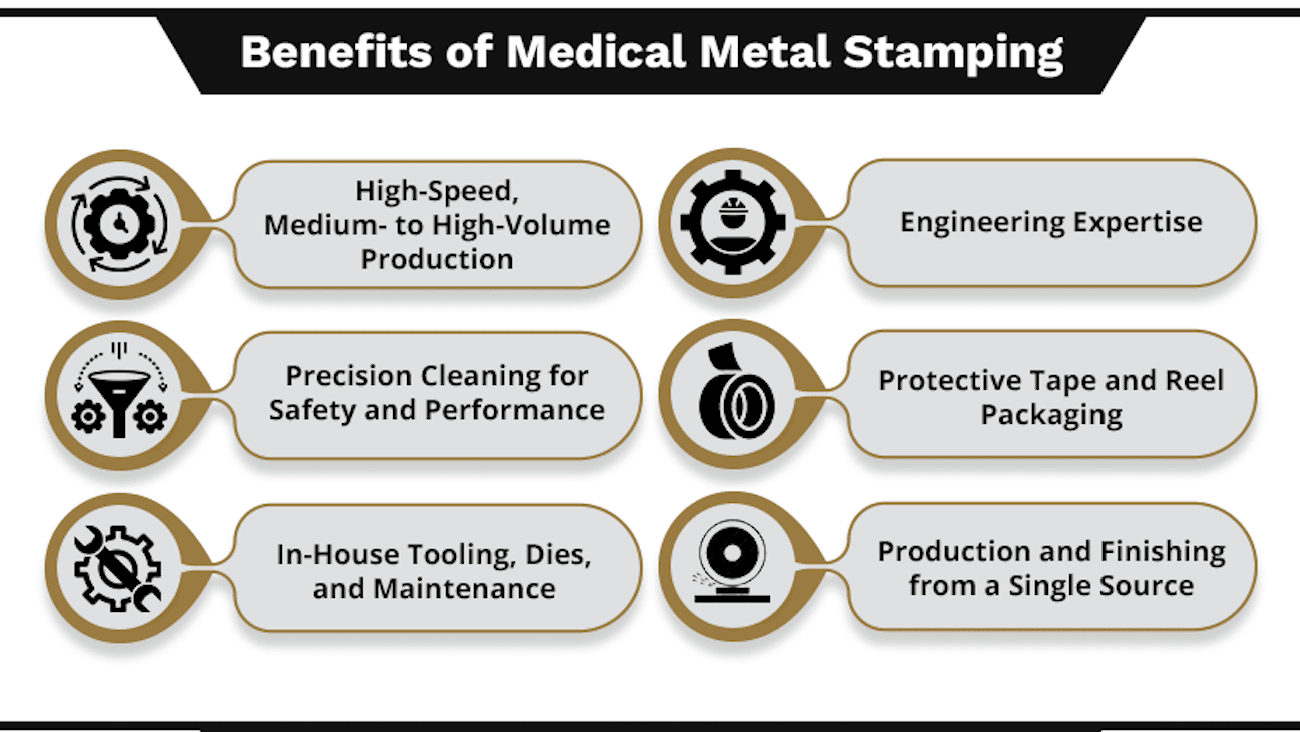

Benefits of Medical Metal Stamping

Medical device metal stamping with progressive dies is a highly automated process, which makes it an excellent choice for medium and large production runs. Our metal stamping capabilities offer you these benefits:

High-speed, medium- to high-volume production with tight tolerances. Presses can run hundreds of parts per hour for quick turnaround.

- Engineering expertise. We have a team of engineers who will review your part prints for manufacturability and to find ways to use less material and reduce manufacturing steps. Small “tweaks” add up to savings without sacrificing functionality.

- Precision cleaning for safety and performance. Parts used in medical devices and equipment must meet strict requirements for cleanliness in addition to quality. We can clean precision stamped parts to specifications, including holding particle sizes to less than 200µm for parts that have pre-plated raw material.

- Protective tape and reel packaging. We use tape and reel packaging to encapsulate individual parts, which ensures they remain in clean, ready-to-use condition during shipping and in storage. We can also design custom packaging depending on your needs. Read how we helped one of our customers with their packaging needs here.

- In-house tooling, dies, and maintenance. CEP Technologies will build tooling and dies for your unique project and maintain them for the lifetime of your production run. That means prompt turnaround and consistent part quality, even with extremely tight tolerances. You also have the option of transferring your existing tooling.

- Production and finishing from a single source. All parts are stamped to your specifications with highest-quality materials. Several finishing processes are also available including plating, polishing, heat treating, and anodizing. Finished stampings are cleaned and packaged for shipping to your facility in ready-to-use condition.

High-quality, Efficient Progressive Die Stamping with CEP Technologies

Whether you need 25,000 or 100,000,000 pieces a year, our company, IATF 16949:2016 and ISO 14001:2015 certified with TUV Rheinland of North America, can meet or exceed your requirements. Please contact us, request a quote, or request a free sample kit to see some examples of what we can manufacture for you.