CEP Technologies provides a range of cleaning methods that meet ISO 16232 standards.

Precision Stamping is On-trend with Alternative Fuel and Semi-autonomous Vehicles

The rising popularity of semi-autonomous and “smart” vehicles means drastic changes to equipment and components in new cars. Here’s our take on the situation.

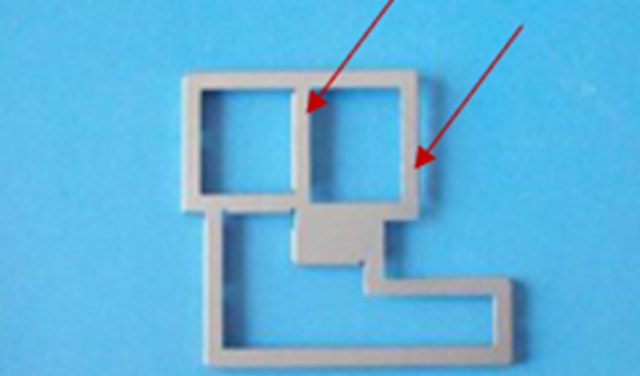

Un-mixed Signals: Interference and shielding in the expanding realm of compact electronics

Electromagnetic and radio frequency interference have always been a concern with electronics, but with more devices in proximity to each other and more computing power housed in each, radiation and sensitivity to emissions are more critical than ever before.

Garnett Component Sales Inc. Exclusive Manufacturers’ Rep For CEP Technologies’ Small, Precision Metal Stampings

We are excited to be working with Garnett Component Sales to bring an exceptional experience to our new and returning customers. Learn more about our partnership

4 Ways to Get the Most Out of Your Next Prototyping Project

Most new parts change several times as they evolve from a conceptual drawing to a physical object in the real world. By the time a new part is ready for prototyping, you’ve made drawings, calculations, and prepared extensive documentation (and if you’re working within the automotive industry, you’ve also spent countless hours on the Production…

Need Something More From Your Stamping Vendor? Why Partnering With a Strategic Supplier Makes Sense

By developing a good working relationship with your stamper you can save money and get added value for your investment.

A Pressing Matter: Balancing Part Cost and Quality in Micro Stamped Parts

As OEMs and aftermarket equipment companies tighten tolerances, manufacturers face the challenge of producing stamped parts that meet and exceed their customers’ requirements. Poor die design along with scrapped or reworked parts cost everyone involved time and money. It’s critical to get it right the first time and every time.

Real-World Precision Stamping: Dimensional Specs Are Not Enough

Most designers of stamped parts don’t need to be convinced of the value of specifying tolerances as a regular practice. But including dimensions and tolerances isn’t a foolproof solution. When you spend time thoughtfully developing a part with features as elegant as they are functional, it’s all too easy to focus on design to the exclusion of manufacturing realities.

CEP Technologies Launches New Site To Support Manufacturers That Need Miniature To Small Progressive Metal Stampings

YONKERS, New York (September 11, 2019) CEP Technologies Corp. has launched a new website for manufacturers that need custom miniature to small progressive stampings.