At CEP Technologies, we are a global source for miniature to small thin gauged progressive metal stampings, providing electromagnetic interference (EMI) and radio frequency interference (RFI) shielding solutions, electrical and automotive parts components, press fit pins, and more.

EMI shielding protects electronic devices and equipment from signal disruption caused by external electromagnetic signals. EMI shielding can also act as a barrier so the signal produced by a given product doesn’t interfere with surrounding components.

Fitting EMI/RFI Shielding Into the Design of EV/Hybrid Vehicles

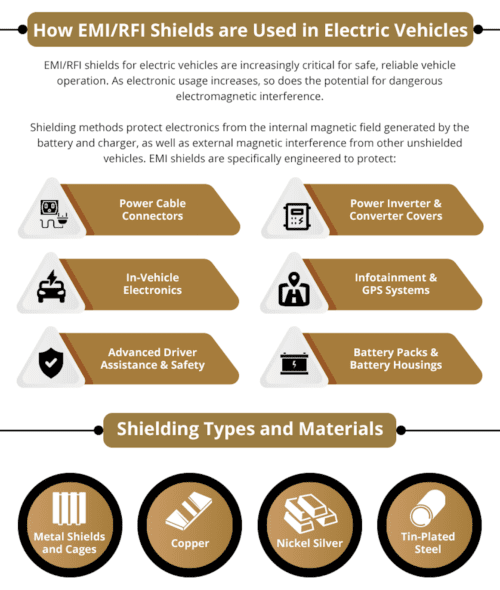

With EV and hybrid vehicles, the risk of interference is even higher. EV and hybrid vehicles contain the above mentioned electrical systems on top of generating large electromagnetic fields around the battery cables and the engine, as well as the charger and the battery. These added elements can negatively affect the various electronic components and systems within the vehicle.

To mitigate this issue, it’s crucial to include effective EMI/RFI shielding into the design of EV and hybrid vehicles. Developing protective enclosures for the vehicle’s circuits and cables can significantly reduce interference from mutual and outside signals and prevent subsequent issues. This ensures that the vehicle runs smoothly and reliably.

Why Use EMI/RFI Shielding for Your EV and Hybrid Vehicles?

EV and hybrid vehicles emit significant amounts of electrical and electronic content within a confined space, making them very susceptible to EMI. The conductive and radiated emissions from the various electrical systems contained in EV and hybrid vehicles can disrupt circuits and lead to conditions ranging from minor inconveniences to dangerous losses of vehicle functions.

Without proper EMI/RFI shielding, the vehicle’s overall safety and performance can be drastically affected. By implementing the necessary EMI/RFI shielding techniques, you can shield sensors and electronic control units (ECUs) from interference, safeguard communication between ECUs in electric vehicles and cameras, and guard the function of the various electronic components within the vehicle.

Choosing the Right EMI/RFI Shielding Techniques

When choosing the right EMI/RFI shielding techniques, it’s important to consider when and how to implement them into the design. Automotive manufactures should prioritize EMI shielding at the beginning of the design process, during the design of the electronic components themselves. Doing so prevents discovering EMI problems on the assembly line, where shielding solutions can take up extra space and become far more expensive.

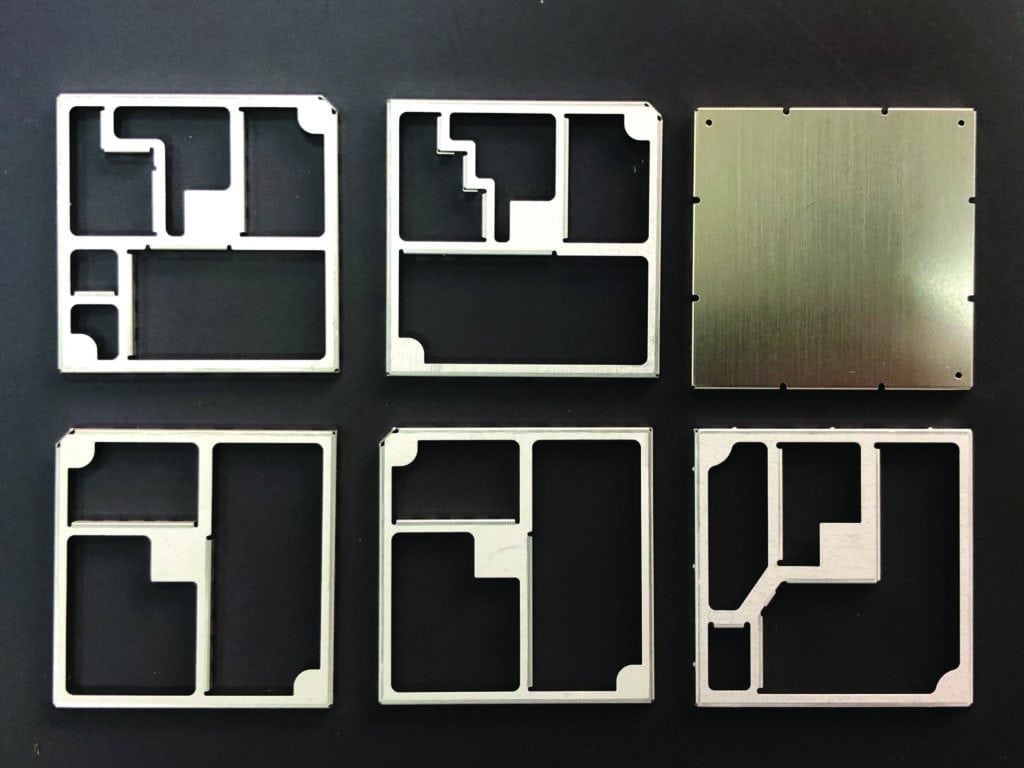

Optimally, EMI shielding techniques should be designed to fit tight tolerances while still being repeatable and scalable to meet long-term needs. For example, manufacturers can turn to chemical etching processes to create EMI shielding parts that are as thin as 0.0005’’ and can be consistently replicated in the manufacturing phase.

EMI/RFI Shielding From CEP Technologies

In the complex, ever-changing EV industry, you need an EMI/RFI shielding manufacturer with extensive experience in the manufacturing of custom shielding solutions for complex and innovative parts.

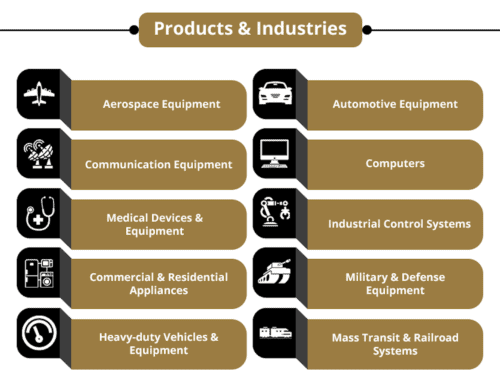

At CEP Technologies, we are a global provider of metal stamping solutions, including custom EMI/RFI shielding components. Our experience in the manufacturing of custom EMI/RFI shields allows us to work with your design team to assist in dimensioning and tolerancing and raw material selection in order to provide a cost effective and efficient solution. Our high-quality metal shields can protect the various electrical systems within EV and hybrid vehicles from EMI and RFI damage.

- Aerospace equipment

- Automotive equipment

- Communication equipment

- Computers

- Medical Devices and equipment

- Industrial control systems

- Commercial and residential appliances

- Military and Defense equipment

- Heavy-duty Vehicles and equipment

- Mass transit and railroad systems

- Telecommunications

Contact us today to learn more about our custom EMI/RFI shielding capabilities, or request a quote to get started.