Custom Metal Stamping

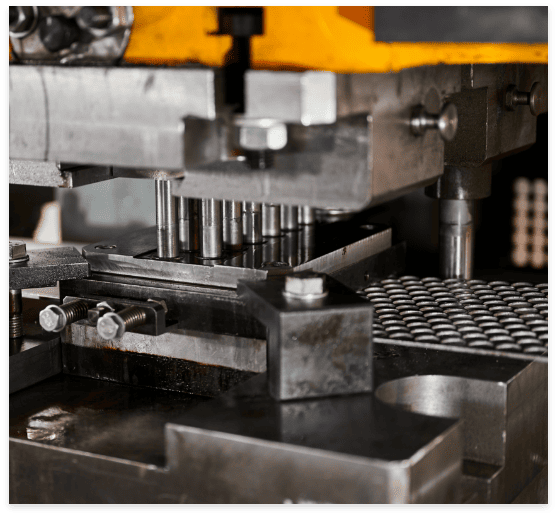

Progressive Metal Stamping Service Overview

CEP guides metal strips through a press from a coil. Each strip advances through the machine. Custom-made upper and lower tooling and dies align the strip and contain sequential features (i.e., stations) to form and cut the metal.

What is Metal Stamping?

- Coining: Dies press on the material to flatten or squeeze it.

- Bending: Upper and lower die plates combine to fold or bend the metal at an angle, such as a V or L.

- Flanging: The piece goes through a material removal process in which a cutout is stamped and becomes the finished part.

- Shearing: A machine cuts material away from the strip along a straight line, at an angle or parallel to the strip.

- Piercing: A shape is cut out of the material, and the cutout, or slug, is discarded as scrap.

- Notching: A V-shaped section of the part is removed to enable a bend or fold in the finished piece.

Benefits of Our Metal Stamping Service

High-speed metal stamping is an efficient process for manufacturing parts in high volumes with accuracy and precision. It is an automated process that can create hundreds to thousands of identical parts quickly.

There are many cost and time-saving advantages to working with CEP:

- Custom production based on your concept or drawings

- Expert support from our design and engineering team

- Fast, high-volume production flexibility

- Ability to achieve complex part geometries and features with tight tolerances

- Wide range of metal types available, including pre-plated material

- Option to draw on your stamper’s experience to optimize your design and materials

- Part availability when you need it

- One-stop production from a single vendor with finishing processes, cleaning, packaging and tape and reel encapsulation.

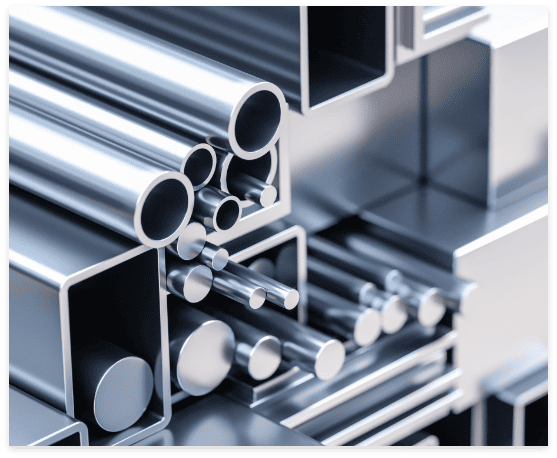

Types of Metals

Many types of material are available in coil form for progressive stamping. CEP offers these metals for your project

- Stainless Steel

- Aluminum

- High- and low-carbon cold-rolled steel

- Pre-galvanized steel

- Nickel-plated steel

- Precious metals

- Brass

- Bronze

- Copper

Miniature to small parts are stamped using metal thicknesses from 0.002” to 0.080”. Pre-plated materials save on manufacturing time and costs in certain applications.

CEP makes recommendations by considering the physical stresses, temperatures, conductivity requirements, solderability, strength and hardness needs of the design.

Progressive Precision Metal Stamping for Different Industries

We tailor our custom progressive metal stamping services to multiple industries.

Automotive, EV and E-Mobility

We help create components for electronics, door locking systems, infotainment systems, GPS systems, advanced driver assistance systems (ADAS), sensor parts, fuel pumps, fuse panels, heat sink plates and more. Our work encompasses parts for aerospace vehicles.

Electronic Devices, Systems and Products

Trust CEP to assist with home, business and industrial components like battery and switch contacts, relay components, EMI/RFI shields, lighting fixtures, smart home management devices, remote controls, appliances and security systems.

Lighting

CEP gets involved with industrial, commercial and consumer/residential lighting projects such as switches, contacts, clips, terminals and other miniature-to-small components used in fixtures and peripheral equipment.

Medical and Healthcare Devices, Equipment and Settings

Emerging and established medical devices and technologies require tiny stamped parts for disposable/single-use IV pumps, wearable devices, imaging equipment, device housings and diagnostic and treatment tools.

Aerospace

CEP has experience with components used for telecommunication, electrical and mechanical systems tailored to aerospace applications. Create components with tight tolerances that remain lightweight for your needs.

Telecommunications

Depend on CEP for solutions used in main switching systems for telephone panels/switch boxes, power protection equipment and routers. We also provide pins, clips, contacts and brackets to secure components.

Get a Quote for Custom Metal Stamping Services

CEP partners with you from concept, design and prototyping through material sourcing and production. We offer customers medium-to-high-volume annual production runs of 25,000 to 100,000,000 pieces.

You can contact us for a free quote.