Global presence, world-class experience, personal service.

CEP Technologies Corporation is a global provider of metal stamping solutions with significant experience producing custom EMI shielded enclosures and RFI solutions. CEP manufactures custom EMI shields that help control the effects of electromagnetic and radio frequency interference (EMI and RFI).

Choose from copper, brass, nickel, silver, steel, tin, and more. Our high-volume metal stamping capabilities and broad selection of raw materials allow us to serve a wide range of industries and applications.

Our EMI and RFI Shielding Materials

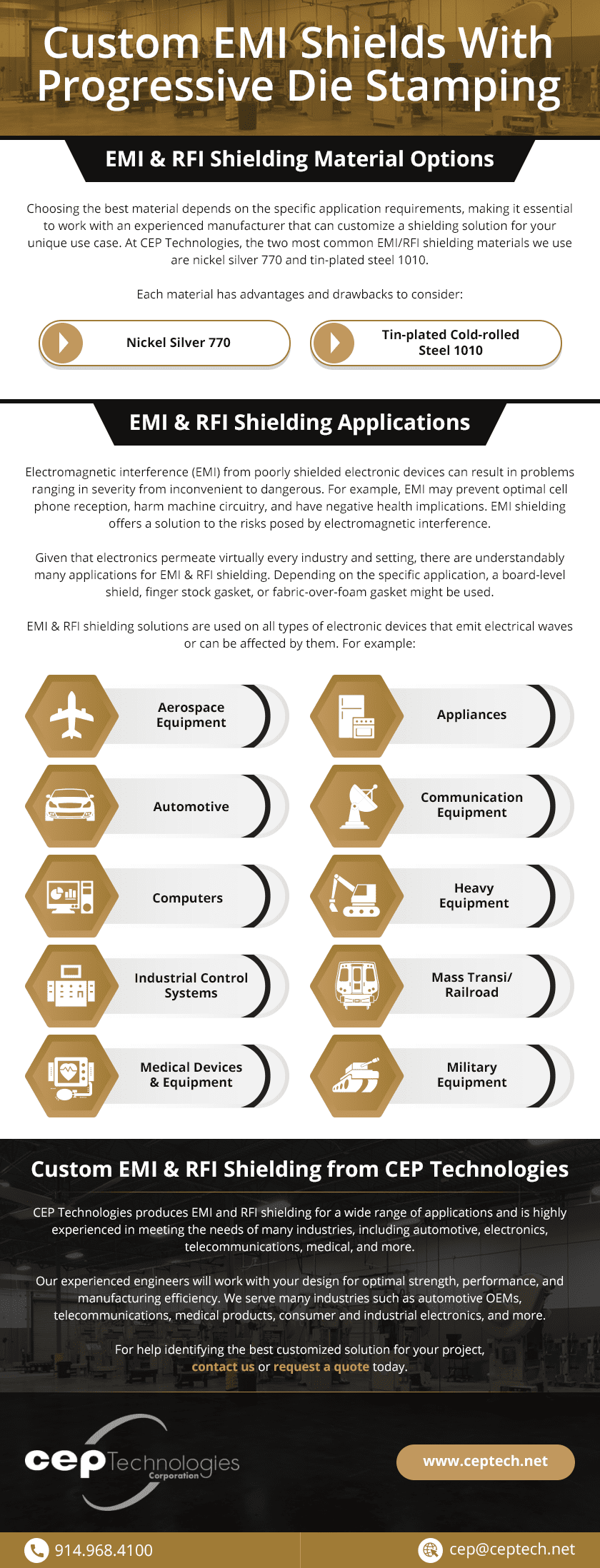

Choosing the best material depends on the specific application requirements, making it essential to work with an experienced manufacturer that can develop custom EMI/RFI shielding solutions for your unique use case. We primarily use two custom EMI/RFI shielding materials:

- Nickel silver 770: This non-magnetic, solderable, and corrosion-resistant material is an optimal choice for shielding high-frequency ranges.

- Tin-plated cold-rolled steel 1010: This cost-effective material works best in applications that require shielding at low-frequency ranges. Surface plating is required to make it solderable, and this material does not perform well in corrosive environments.

EMI and RFI Shielding Applications

Electromagnetic interference from poorly shielded electronic devices can result in problems ranging in severity from inconvenient to dangerous. For example, EMI may prevent optimal cell phone reception, harm machine circuitry, and have negative health implications. EMI shielding offers a solution to the risks posed by electromagnetic interference.

Given that electronics permeate virtually every industry and setting, there are understandably many applications for EMI and RFI shielding. We may use a finger stock gasket, fabric-over-foam gasket, or board-level shield based on your specific application.

EMI and RFI shielding solutions are used on all types of electronic devices that emit electrical waves or can be affected by them.

- Aerospace and automotive: EMI/RFI shielding protects airplane safety and mission controls against high-altitude nuclear electromagnetic pulse (HNEMP). It also blocks EMI from affecting electronic control units (ECUs), sensors, and other devices in vehicles.

- Consumer appliances and electronics: Custom shielding solutions protect appliance components from EMI generated by other devices in homes and businesses. They also prevent access to stored data on RFID chips, safeguarding components from interfering with each other.

- Health care: Small EMI shields protect implantable devices, X-ray machines, lab equipment, life support systems, and other critical medical equipment from interruption.

- Military equipment: EMI and RFI shields increase or complement security systems, protecting against EMP weapons.

- Industrial applications: Custom EMI shielded enclosures protect industrial equipment from unwanted frequencies.

Custom EMI and RFI Shielding From CEP

CEP produces EMI and RFI shielding for a wide range of applications and is highly experienced in meeting the needs of many industries, including automotive, electronics, telecommunications, medical, and more.

All of our stamping press tooling is designed and built in-house. Our engineers create designs for optimal performance and manufacturability. We also offer prototyping services with a lead time of 10 days or less to help our customers test design concepts in advance of full production. We provide numerous value-added services, such as reel-to-reel processing, barrel plating, tape and reel packaging, precious metal coatings, e-coating, deburring, and more.

For help identifying the best custom EMI and RFI shield solution for your project, contact us or request a quote today.

“Congratulations to the whole CEP team on achieving technical cleanliness specifications for particle size under 100 microns! This is an important milestone in your manufacturing capabilities.“

A CEP Customer