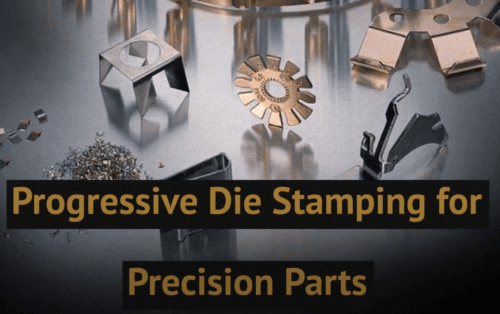

Progressive Die Stamping for Precision Parts

What Is Progressive Die Stamping?

PROGRESSIVE STAMPING IS DISTINCT FROM OTHER TYPES OF STAMPING, SUCH AS:

- Transfer Stamping

Transfer Stamping

Parts are separated from the strip early in manufacturing and are transferred to different stamping machines, whereas progressive stays connected to the strip until the end of the process. - Fine Blanking

Fine Blanking

A high pressure operation in which a single workpiece is clamped into position for blanking and is then ejected. - Four Slide Stamping

Four Slide Stamping

Unlike progressive stamping, this method uses no dies, and instead uses sliding tools (often but not always four of them) that strike the workpiece from different directions to shape it.

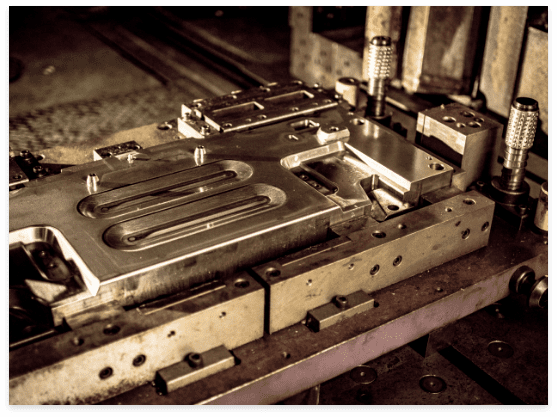

The Role of Tooling and Dies

Tooling is a broad term for the mechanical components within a press that hold dies and help direct metal strips through the press. Plates, jigs, fixtures, and the actual dies are examples of tooling.

Dies are a specific type of tooling that cut, shape, or remove portions of the material to create the actual parts.

When selecting a stamper for custom precision parts, determine if you will transfer your existing tooling (if available) or have your stamper make new ones. While it may seem like an easy decision to use what you already have, an experienced stamper may be able to maximize efficiency and lower scrap rate when building a new tool.

Common Materials for Progressive Die Stamping

A VARIETY OF METALS ARE USED IN PRECISION DIE STAMPING, INCLUDING:

- Stainless steel

- Aluminum

- High- and low-carbon cold rolled steel

- Pre-galvanized steel

- Nickel-plated steel

- Brass

- Copper and copper alloys

CEP works with blanks up to 6” x 6”, and thicknesses less than 0.080,” as well as a maximum of 60 tons per press.

Why Choose Progressive Die Metal Stamping Services From CEP?

Progressive die stamping is a fast, economical way to manufacture a large volume of custom parts. The process is highly repeatable, which means more in-tolerance parts and less scrap and rework.

At CEP, we provide project lifetime tool maintenance. The ability to repair, sharpen, and maintain tooling and dies saves you time and money in the long run instead of having to manufacture new tooling at future points in production.

- Engine, transmission, and advanced driver assistance systems (ADAS) sensors

- Vehicle communication systems

- EMI/RFI shields for vehicles and consumer electronics

- Custom battery contacts

- Key fobs and door lock components

- Ignition and fuel pump components

- Vehicle Infotainment systems

- Clips, pins, and brackets

- Medical devices

Our Progressive Die Stamping Process

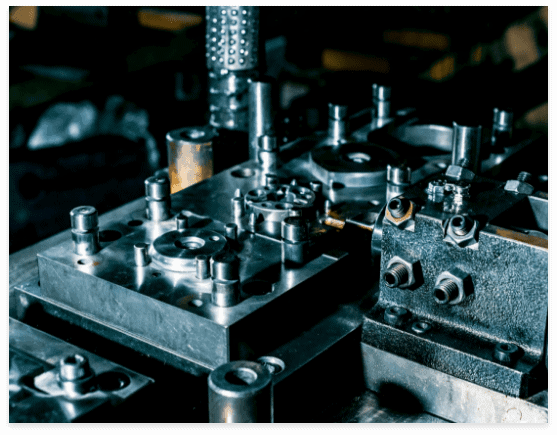

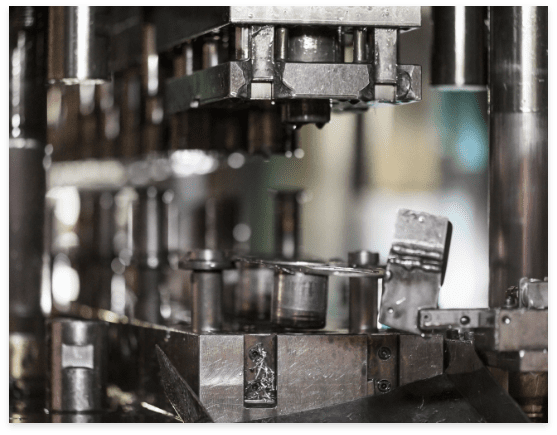

Our expert team can design and build progressive die stamping parts to accommodate nearly any part or production need. Once the tools are ready, we can start the actual stamping process.

The first step of the progressive die stamping process is setting the tool into our power press and adjusting the feed settings. Next, the machine operator carefully passes the coil strip material through the tool in sequence. This is especially important as there are multiple stamping stations present in the setup.

The final step of the process is running the machine. Depending on size and geometry of the part, each stroke of the press can produce a single or multiple parts.

Finding the Right Stamping Partner for Your Needs

While the actual precision die stamping is important, there are more things to consider when choosing a stamping partner. After all, the success of your stamping project directly impacts the success of your final product and your bottom line.

Be strategic when choosing a stamper. It’s worth the time to discuss things like total cost of ownership of tool and die manufacturing and maintenance, their design expertise and ability to suggest design modifications to improve manufacturability, value added services offered like cleaning and packaging, and vendor managed inventory (VMI) and purchasing agreements for raw materials. Take a deep dive on these and other ways to assess a stamping vendor here.

Partner With CEP for Progressive Die and Stamping Services

When you work with CEP, you get more than just a precision die stamping vendor — you get an experienced partner. We can review your design, discuss options for materials, and keep your project moving. Please contact us for a free quote on your custom miniature to small stamping or prototyping project.