CEP Technologies Corporation supplies customers worldwide with the custom miniature and small progressive stamped parts they need in their industries. On this page, you’ll see how our capabilities benefit the power protection industry. This includes utility and power plants as well as appliances, consumer electronics, desktop computing, and IOT (Internet of Things) applications.

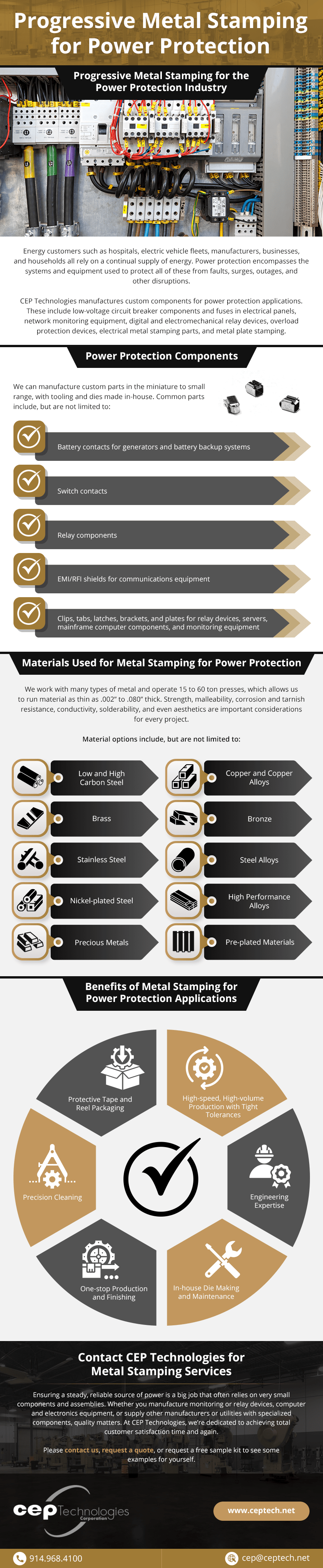

Progressive Metal Stamping for the Power Protection Industry

Energy customers such as hospitals, electric vehicle fleets, manufacturers, businesses, and households all rely on a continuous supply of energy. And on a smaller scale, appliances, electronics, and communications equipment need a steady source of power too. Power protection encompasses the systems and equipment used to protect all of these from faults, surges, outages, and other disruptions.

CEP Technologies manufactures custom components for power protection applications. These include low-voltage circuit breaker components and fuses in electrical panels, network monitoring equipment, digital and electromechanical relay devices, overload protection devices, electrical metal stamping parts, and metal plate stamping.

When you need an electromechanical part stamping partner who understands your goals and precise industry regulations, CEP is here to deliver. Our metal stamping tools for electrical parts and components are capable of meeting tight tolerances and developing the smallest, most complex parts you need for your operations. Our services also include finishing and packaging.

Power Protection Components

We can manufacture custom small and miniature parts, with tooling and dies made in-house. Common parts include, but are not limited to:

- Battery contacts for generators and battery backup systems

- Switch contacts

- Relay components

- EMI/RFI shields for communications equipment

- Clips, tabs, latches, brackets, and plates for relay devices, servers, mainframe computer components, and monitoring equipment

Materials Used for Metal Stamping for Power Protection

Our electrical metal stamping equipment can operate using a range of metals, with presses able to use up to 60 tons of force on materials that are from .002” to .080” thick. Strength, corrosion, malleability and tarnish resistance, conductivity, solderability, and even aesthetics are important considerations for every project. We can also provide coatings, polishing, heat treatment, and anodizing services.

Our extensive material options include:

- Low and high carbon steel

- Copper and copper alloys

- Brass

- Bronze

- Stainless steel

- Steel alloys

- Nickel-plated steel

- High performance alloys

- Precious metals

- Pre-plated materials

Our experienced team of engineers and stampers will collaborate with you to choose a cost-effective option that meets your design requirements, schedule, and budget.

Benefits of Metal Stamping for Power Protection Applications

Progressive stamping is a highly automated process, which results in a high level of repeatability for consistent parts over time. This makes progressive stamping an excellent choice for medium and large production runs. Some of the benefits of this process include:

- High-speed, high-volume production with tight tolerances. Automated presses can run hundreds of parts per hour, saving time and money without compromising part quality.

- Engineering expertise. Our team includes engineers to review your part prints for manufacturability and to find ways to use less material, fewer steps, or make minor changes that add up to savings and highest quality.

- In-house die making and maintenance. CEP Technologies will build tooling and dies, and maintain them for the lifetime of your production run. You’ll know we always have them available, and you can expect consistent quality part after part. Of course, you also have the choice to transfer your existing tooling to us for maintenance and production. Learn more about your options here.

- One-stop production and finishing. All parts are stamped to your specifications with highest-quality materials. We offer finishing processes including plating, polishing and heat treating. Finished stampings are cleaned and packaged for shipping to your facility in ready-to-use condition.

- Precision cleaning. CEP Technologies can clean precision stamped parts to specifications, including holding particle sizes to less than 200µm for parts made from pre-plated raw material.

- Protective tape and reel packaging. Parts remain in ready-to-use condition during shipping and in storage with tape and reel packaging that encapsulates each individual part. Or we can design customized packaging depending on your needs. Read how we helped one customer redesign their packaging for part separation and ease of access.

Contact CEP Technologies for Metal Stamping Services

Ensuring a steady, reliable source of power is a big job that often relies on very small components and assemblies. Whether you manufacture monitoring or relay devices, computer and electronics equipment, or supply other manufacturers or utilities with specialized components, quality matters. At CEP Technologies, we’re dedicated to achieving total customer satisfaction time and again.

Put our international production facilities to work when you place your order for high-volume electrical component metal stamping. We are capable of exceeding your requirements, even at production runs of over 100,000,000 pieces a year. Request a free sample kit to see our products firsthand or request a quote today. You can also contact us to learn more about our work with metal stampings for the electrical industry.